Mobile racks

Many enterprises are worried about the lack of storage space in warehouses. Mobile racking systems are the best solution of this problem. These racks are designed to maximize storage space via mobile platforms, that serve as the basis for the installation of frames of the rack. Platforms are set in motion by electric drive, all racking systems are controlled with a single remote control. If you need an access to a specific cell the required number of rows of movable shelving opens with this remote. This ensures maximum use of storage volume with the ability to access each object at any time.

Mobile systems consist of usual pallet racks and mobile platforms on which they are installed. Racks are moving on guide rails, which are mounted into the concrete floor. Storage equipment passes through them freely. Rails for mobile racks can be equally integrated into the floor during the construction of a new warehouse and in the existing one.

Advantages of mobile racks

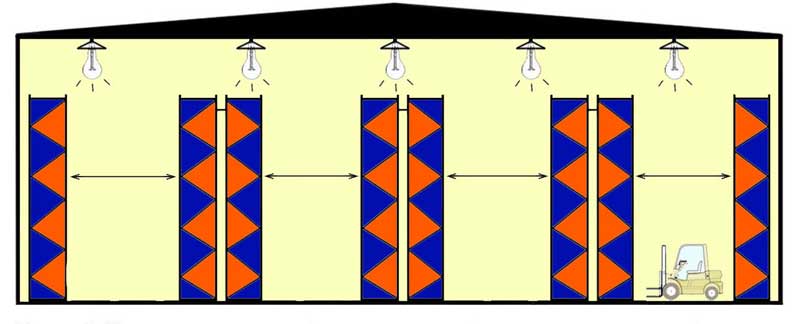

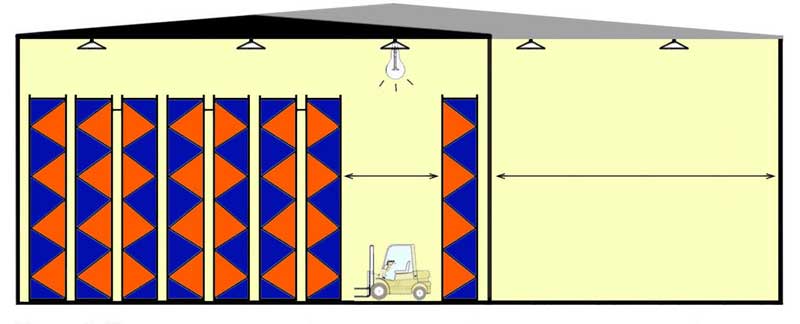

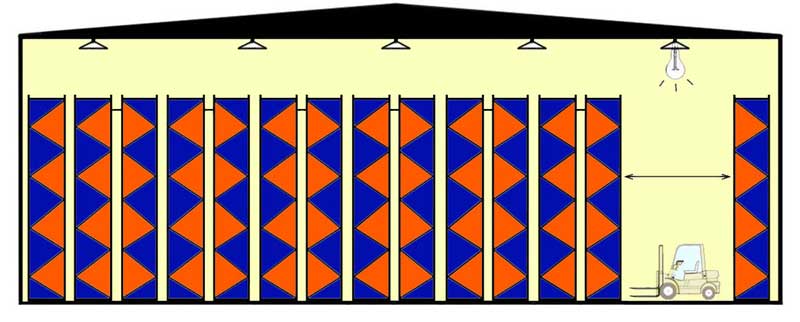

Mobile racking has a number of advantages in comparison with stationary systems. In the classical placing of ordinary racking constructions (Fig. 1) wide aisles are left between the rows for warehouse equipment. Mobile racking systems needs only one pass (Fig. 3), as the chosen platform is moving while the others remain closed in blocks and take up minimal space. As a result, the same amount of racks occupy only 50% of the warehouse (Fig. 2).

Thus, the installation of available racks on mobile platforms is the most efficient in terms of investment and the quickest way to increase storage capacity in the existing warehouse. Standard pallet racks can be replaced by doubled amount of mobile racks. You can also free up half of storage space for expanding production capacities or other needs. If the object is in the process of construction, incorporation of mobile systems into the project allows you to restrict half of the storage square and to save on its construction and further exploitation.

Thus the application of mobile racking provides:

- increasing of storage capacity to 80-100% in comparison with standard racks;

- reducing the cost of maintaining a warehouse;

- minimizing the investment and operating costs;

- wide storage opportunities;

- the possibility of remote control.

Fig. 1 Classic placing of stationary pallet racks. Area of 800 square m., 1008 p/p.

Fig. 2 Mobile racking systems. Area of 450 square m., 1008 p/p.

Fig. 3 Mobile racking systems. Area of 800 square m., 1764 p/p.

The space between standard pallet racks occupies more than half of the warehouse and requires constant expenses for its lighting and heating. Rooms with controlled atmosphere, such as refrigerators and freezers, require the most significant energy costs. Mobile racks can significantly reduce these costs throughout their life cycle, so the price will be totally paid off.

Advantages of IMVO mobile racks:

- decline in investment in the creation of one pallet of 38% due to increased storage capacity by 93%;

- guide rails are made of high-strength steel and are installed with extreme precision, which guarantees long lifetime;

- high quality pallet rack.